Bottleneck in Production

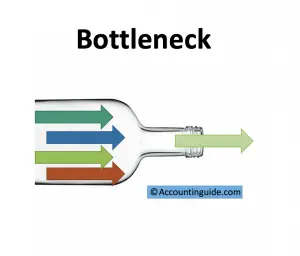

Bottleneck is the constraint that limits the overall result of the whole process. Similar to physical bottleneck, it is the point which limits amount of water that flows in and out of bottle.

Bottleneck is the constraint that limits the overall result of the whole process. Similar to physical bottleneck, it is the point which limits amount of water that flows in and out of bottle.

In manufacturing, the bottleneck is the factor that limited the total output of a production. It happens due to one activity in production cannot produce enough output for the next activities to operate at their full capacity. It leads to idle times in the next activities .

Example of bottleneck in production

Manufacture ABC produce clothing, all of products needs to go to process as below:

- 1: Cutting the fabric

- 2: Sewing

- 3: Laundry

- 4: Ironing

- 5: Packaging

Based on the budget plan, they need to produce 1,000 units per day. So each stage in to complete 1,000 units per day.

On 15 November 2018, they can produce only 800 units per day.

After investigation, the company found that laundry in stage 3 can complete only 800 units per day due to machine break down.

Solution

Based on the information provided, we can see that the Laundry stage is the bottleneck of the whole production process. Due to this bottleneck, it causes idle time in Ironing and Packaging stages as they have to wait for completed work from laundry.

To solve this problem, we have to repair the machine to increase the production to 1,000 units. When the laundry process can catch up with others, the whole process will reach its maximize. We will be able to eliminate the bottleneck.

What are the common cause of bottleneck in manufacturing?

| Causes of bottleneck | |

|---|---|

| Machine Breakdown | If there is any machine breakdown during the working process, surely it will be the bottleneck for the whole operation. The next process will need to wait until machines have repaired, there will be idle time or even lead to a long pause of operation. |

| Less skill worker | Working processes are designed to maximize the output only when the workers reach a certain level of skill. They will have enough experience from their working. However, if the majority of one department is the new staffs, so they will not be able to increase their output and it will become the bottleneck. |

| Inappropriate design of workflow | In manufacturing, the process starts with raw material, work in process and ends up as the finished goods. The material needs to move through a few assembly lines in order to complete the process. If one of those line cannot produce enough task for the next assembly lines, it will become the bottleneck. |

| Wrong forecast | If management makes the wrong decision by overestimate one specific product leads to overstock in the warehouse. The storage space will be the bottleneck for the others product. |

Impact of bottleneck to production

- Increase cost (nonvalue-added)

Bottleneck will delay operation, increase idle time which will increase the cost to the company. These costs do not add any value to the finished product or the customers.

- Customer complain

Due to the bottleneck, the operation will be delay and impact on deadline with customer. The longer it delays, the more it will impact to customer. Moreover, as a result of the bottleneck, the company will incur higher costs so they will charge higher prices to their customers.

- Less motivate

The assembly line which contains bottleneck will demotivate as they have to work even higher than their maximum capacity to catch up with the next assembly. Sometime even they work that hard but it still below the others so it will lead to demotivate.

Benefit of bottleneck analysis:

- To reduce cost

Improve bottleneck means that the company will be able to minimize idle time, breakdown and maximum whole production capacity. Hence the output will increase with lower cost per unit.

- Satisfy customer

Since the company eliminates the bottleneck, products will complete according to the schedule at a reasonable price. Customers will be happy to do business with us.

- Increase overall production capacity

Bottleneck is the key factor that can limit whole manufacturing production capacity. When we can solve it, all assembly lines will work at their maximum capacity.

How to solve bottleneck to increase production?

| Suggested solution to bottleneck | |

|---|---|

| Manage work in progress (WIP) | Consider setting up the maximum level of WIP which each assembly line can hold at any specific time. If there are any unusual high WIP, it means that the next process will lack of works. It is the indicator of bottleneck. |

| Add more resource | When we can identify the bottleneck, we need to deeply understand that process and allocate more resource which needs to increase to catch up with other process. |

| Manage the whole workflow | Adding resources is not always a solution, we have to consider the whole picture of the production. Sometimes the bottleneck due to miss arrangement of workflow. If you are not seeing the results you want, perform another workflow audit and consider re-doing the workflow from scratch. |

| Change to batch process | Some operations can decrease time when similar products in the same batch. Workers will increase their learning curve during their work, so they will reduce the time need to complete each product. |

| Try to increase overtime | Increasing overtime in the bottleneck line when we do not have enough resources to add to the process. It will increase the output of the bottleneck for a short time while we try to figure out other solutions. |

| Minimize downtime | If the machine broke down is the main reason, we have to decrease the downtime by increasing repair & maintenance time after working hours. Make sure that technicians are ready for any unexpected breakdown. |

| Separate the bottleneck activities | Breakdown the bottleneck into smaller activities and rearrange resources. There will be a shorter cycle and the output capacity will increase. |