Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is the inventory level in which the company should place purchasing orders to minimize the cost of inventory. The total cost of inventory usually include holding cost, ordering cost and storage costs. It is the most common method that company use to optimize the inventory cost to the minimum level.

Economic Order Quantity (EOQ) is the inventory level in which the company should place purchasing orders to minimize the cost of inventory. The total cost of inventory usually include holding cost, ordering cost and storage costs. It is the most common method that company use to optimize the inventory cost to the minimum level.

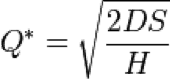

Economic Order Quantity Formula

Where:

Q = optimal order quantity

D = annual demand

S = cost incurred to place a single order, reordering cost

H = holding cost per unit per year, carrying cost

Total inventory cost = purchasing cost + ordering cost + holding cost

EOQ Assumptions:

In order to use EOQ system, the company needs to make a proper estimate which known as EOQ assumption:

- Demand: The company has to estimate the annual demand of raw material, and there is no expected change during the year.

- Reordering cost: The company has fixed contract with suppliers to prevent cost fluctuation.

- Purchase order lead time: The time between placing order and receiving the inventory in warehouse. There is no delay in lead time due to strict contracts with suppliers.

- Cost per unit: it is the fixed cost regardless of purchasing quantity; we ignore the discount on bulk purchase.

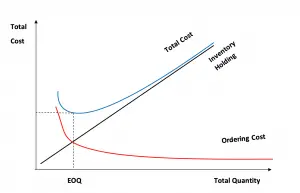

EOQ Graph

To illustrate the concept, let take a look at the EOQ graph below and you will notice that:

- EOQ is the lowest on total cost។

- Ordering cost will decrease if we order in large quantity. We can have lower ordering cost, but not the total cost

- The holding cost will increase due to the large order quantity as we have to store large quantity.

Economic Order Quantity Example

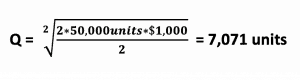

For example, Company ABC is a car manufacturing which purchases most of the component from suppliers all around the world. In order to minimize inventory costs, we have decided to use EOQ to control our inventory level. XYZ is our long-term supplier for tire, and they have agreed with our strict delivery time and quality requirement. How to calculate economic order quantity?

Based on the 202X budget, we have collected some information from production as below:

- Based on preorder, ABC requires 50,000 units of tire for the whole year

- The carrying cost per unit is $ 2 per year.

- The cost per order is $ 1,000.

- Please calculate the EOQ of the tire.

Solution

It means ABC needs to place a new purchase order to XYZ when its inventory level reaches 7,071 units. It will help the company to minimize the inventory cost, which includes purchasing cost, ordering cost, and holding cost. The company need to place order 8 times (50,000 units/7,071 units) per year.

Considering factor before applying EOQ

EOQ will help our company to save holding costs as well as the ordering cost without impact to the production need. However, it is not easy as it sounds, we have to consider some factors before applying this method. Otherwise, it will cause more problems than benefits.

Additional Orders

In normal business operations, the warehouse may place orders only one or two times per year for the same material. But EOQ will increase the number of times which they have to place more orders, base on the above example, we need to place order 8 times per year. It sounds simple, but we need to spend resources on prepare purchase requests, purchase orders, record into accounting system, and prepare payment to supplier.

Suppliers’ Requirement

Are you planning to place an order of 7,071 units to supplier? It is hard to place an order like this. The supplier also has the minimum quantity per order, which depends on other factors such as the nature of material, size and safety. Placing order outside of supplier standard may result in additional cost, and it may not possible.

Inflexibility

As we know, EOQ base on the assumption of fixed demand, which is not the case in real life. So we need to have a proper plan to respond to the change. The warehouse, production, and purchasing department need to work closely. They must take action immediately if the demand different from planning.

What are the Importants of Economic Order Quantity?

There are several important of economic order quantity as listed in the table below:

| Important of Economic Order Quantity | |

|---|---|

| Reduce Storage & Holding Costs | By using EOQ, the company will be able to reduce storage cost & holding cost to the minimum level. They do not need to have a big warehouse which is a waste of money. The company only place the order when production needs, so we don’t need to spend a massive cost on storage. |

| Reduce Ordering Costs | It minimizes the number times which we have to place orders to suppliers. EOQ required us to place orders by only keeping a certain amount of raw material which is enough for the reorder period. Using this method, we will not order less than production need which leads to unexpected reorder. We will be able to plan the annual order at the minimum times. |

| Better Inventory Management | The common issues with inventory management are tracking inventory levels to prevent any over or under stock. EOQ is a tool that will solve all of these and reduce time as well as the cost associated. Moreover, we will be able to reduce the obsolete inventory as only a minimum level is kept in the warehouse. |

What are the Disadvantages of Economic Order Quantity?

Even EOQ provide many benefits but there are still some disadvantages which impact to the entities.

| Disadvantages of Economic Order Quantity | |

|---|---|

| Assumption | EOQ assumes that demand within a year will not change, but not in real life. It will fluctuate base on customer order which is not under our control. It is very hard to have a correct prediction since the beginning of the year. If the demand increase, we will use our inventory faster than expected, so there will be a lack of inventory. On the other hand, we will overstock when the demand decrease, which will increase our holding cost. |

| Purchase order lead time | EOQ assumes that the lead time will fix from the day we place the purchase order until the material arrives in our warehouse. In the real situation, the delivery can be delayed by the supplier due to various reasons. We will face the risk of inventory shortage if the delay happens.

We can reduce this risk by having a fixed contract with the suppliers and issuing the penalty to them if delivery time does not meet. However, there are still some conditions that are not under the control of suppliers such as storm, earthquake, and other disasters. |

| Bulk discount | Sometime suppliers may provide a hug bulk discount to their customers, but we do not take this benefit. As the EOQ system requires to purchase only a certain fixed quantity. High order quantity will increase our holding cost, but bulk discount benenfit may be higher than the cost. If we strictly follow EOQ, which is less flexible, we will lose the opportunity to save some cost. |

| Require monitoring | EOQ require stock controllers who work closely on inventory monitoring. They have to ensure that purchase order is placed when quantity approaching reorder level. Any error in quantifies inventory level will be a risk to production. |