Inventory Control Level

Inventory control level is the method that a company manages its inventory to maintain at a certain level which meets production need and minimize ordering and storage cost.

Inventory control is critical for businesses in order to maintain the level of inventory, track important performance metrics, and improve customer satisfaction. By maintaining a proper inventory level, businesses can avoid the cost of overstocking or obsolescence. In addition, inventory control helps businesses to track important performance metrics such as turnover rates and product availability. This information can be used to improve forecasting and decision-making. Finally, good inventory control can improve customer satisfaction by ensuring that products are available when customers want them. Inventory control is a crucial part of running a successful business.

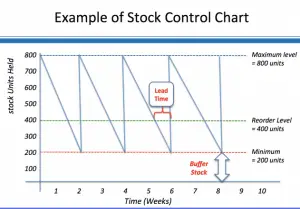

It strongly depends on the reorder level, minimum level, and maximum level. Please refer to the explanation of each term below:

1. Inventory Reorder level

Inventory reorder level is the level of material on hand, which requires us to place the order with the supplier. If we do not place orders on time, it will be a potential risk of raw material shortage.

The correct calculation of the inventory reorder level will ensure that the new ordering arrives when the inventory is approaching zero.

Formula of Inventory Reorder Level

Inventory reorder level = maximum usage x maximum lead time

- Maximum usage: is the maximum daily usage during operation.

- Maximum lead time: is the total of time required from the day company places order until the inventory arrives and is ready to use.

Example

Company ABC produces many kinds of books for the whole country. Our primary material is paper which purchases from the supplier oversea. Based on experience, our manufacturing requires paper from 20T-40T per day depending on the operation.

Due to the far distance, ABC needs to wait 30 days from the date which purchase order was sent to the supplier.

When is the appropriate time that ABC needs to place an order without any impact on production?

Solution

Calculate the reorder level:

Inventory reoreder level = 40T x 30 days = 1,200 Tones

It means that when papers’ quantity decrease to 1,200T, we need to place an order with the supplier. In case our operation runs at the maximum level, we still have enough paper to support our production for 30 days when we are waiting for a new order.

Note: some companies may require their inventory to stay above a certain level which is called Safety Stock. Rather than allow stock level to decrease to zero, the company only let the stock level decrease to the Safety level.

2. Inventory Minimum Level

It is the inventory level that the company needs to maintain during the ordinary course of business to prevent any shortage. When raw material reaches this level, management needs to ensure that proper communication has been made with the supplier. This method is prepared for the case when it takes longer than the standard delivery. When inventory falls below the minimum level, the company faces the risk of material shortage.

Formula of Inventory Minimum Level

Minimum level = Reorder level – (average usage x average lead time)

| Advantages of inventory minimum level | Disadvantages of inventory minimum level |

|---|---|

| Efficient and effective: by keeping stock at this low level will help us to manage our capital effectively, it is not locked with inventory value. We only keep enough raw material for our production. | Risk of inventory shortage: Keeping this low stock level, the company will face a higher risk of stock shortage if there are some unexpected changes in this system. |

| Lower storage cost: with this inventory level we do not need to spend much on the warehouse to store all of them. | Getting stock on time will be complicated and expensive. The company needs proper contract terms with suppliers in order to deliver material on time with a strict deadline to prevent any shortage. This can limit us from getting a contract with suppliers who may have a better deal besides delivery time. |

| To catch up with the market: for industry with a short life cycle (Fashion) that needs to update product frequently, keeping less stock will help to reduce obsolete material when the market change. | Too dependent on suppliers. If we use this method, it means that we purely rely on our suppliers. If they fail to deliver material, our production will stop too. We may have some compensation from them as part of the purchase agreement, but we have a bad reputation with customers. It will impact our revenue in the long term. |

3. Inventory Maximum Level

Inventory maximum level is the warning level at which raw material or finished goods are the potential waste due to obsolete. Raw material has reached a level that is more than production’s needs. When inventory is higher than this level, it will be overstock which incurs higher storage costs and face obsoleteness for short-term material.

Formula of Maximum Inventory Level

Maximum level = Reorder Level + Reorder quantity – (minimum usage x minimum lead time)

| Advantages of inventory maximum level | Disadvantages of inventory maximum level |

|---|---|

| Easy and cheap to manage. Managements, as well as the company, do not need to worry much about the stock level as they are more than production needs. | With a high inventory level, the company must pay a high holding and storage cost. |

| With a high inventory level, the company will have more time to prepare if a market change such as a price increase. We can delay our order with the supplier until the price drop to normal. | Higher risk of obsolete. The higher the inventory level, the higher the risk of obsolete inventory which will increase company costs. Some raw materials may not be obsolete, but their quality will decrease over time and impact our finished product. |

| Using this method, the company can take advantage of bulk discounts. Usually, suppliers will offer a better deal when we place a high volume order, it will help us to save cost. | We need to use cash to purchase that high inventory level, it will lock our capital from use in other areas such as expanding new factories, purchasing new equipment, and designing new products. |

Just in time

Just in time (JIT) refers to a production strategy that involves manufacturing goods only as they are needed. The goal of JIT is to minimize waste and optimize efficiency by eliminating the need for excess inventory. In a JIT system, raw materials and components are delivered to the factory only as they are needed for production. This approach reduces storage costs and minimizes the risk of obsolescence. It also ensures that finished products are shipped to customers as quickly as possible. JIT also encourages workers to be more efficient and productive, as they know that any delays in the production process can have a direct impact on the bottom line.

While JIT has been widely adopted by manufacturers around the world, it is not without its challenges. managing a JIT system requires careful planning and coordination, as even a small disruption in the supply chain can have a major impact on production. As a result, JIT is best suited for organizations that have stable demand and predictable patterns of customer behavior.